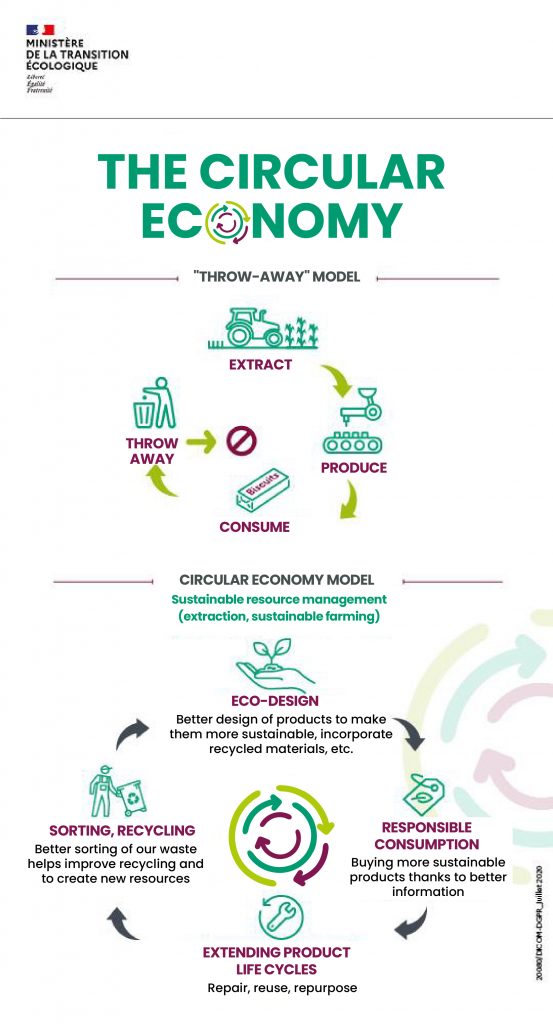

Going from a linear model to a circular one while remaining efficient – it’s all a question of design! Design of the products, of the production processes and of the Supply Chain itself.

The time has come; the circular economy is on the move!

Consumers are now aware of the limits of our planet’s resources and institutional stakeholders have transformed intentions into regulations; notably, through the CSRD (Corporate Sustainability Reporting Directives – European Green Deal), which obliges companies with a turnover greater than €150 million in Europe to publish an extra-financial report.

The performance of a company will therefore be reflected (at last!) according to the 3 components of the “Triple Bottom Line”:

- Environmental performance: what is the impact of my activity on my company, on my suppliers and on my customers for the entire lifespan of the product?

- Societal performance: how do my activities respect the rights of people who are directly and indirectly affected?

- Economic performance: because – no surprise here! – a company can only survive if its economic results are at the expected level.

Circular thinking therefore aims to limit the environmental footprint of a company, whether for products or services. As such, the Supply Chain is on the front lines for adapting to change.

If we look back, the historical definition of Supply Chain Management indicates that we must take into account 4 types of flows in a linear mode:

- Physical flows

- Information flows

- Financial flows

- Return flows

But in a circular mode, these flows can be parallel – but not only because we seek iteration in the use of materials, components, co-products, etc., and thus generate new physical flows which will have to be managed.

How will this idea of circularity translate into practice?

Companies have already begun to embark on reflections on this subject: some out of conviction, others out of obligation. What is certain is that current Supply Chain professions are affected in every aspect by this change which is currently underway.

Every decision made on the choice of supplier, the modification of a means of production, the choice of a method of transport, etc., will have an impact on the overall Supply Chain. Are we ready at all levels to drive this change? Here are some pertinant details:

- Are all buyers aware of the company’s liability when selecting a supplier?

- Are suppliers aware of the impacts of the decisions made regarding the configuration of supply batches on the carbon footprint of the company?

- Are the flow architects involved in the choices of material recycling, storage site location, and management of stocks of recycled materials?

- Do flow designers really have all the levers necessary for making the supply chain more virtuous?

- Are companies really ready to absorb the additional costs linked to the initialisation of circular processes?

- Etc.

Circularity will exacerbate this need for a systemic and non-linear view.

We remain convinced that a Supply Chain cannot be structured simply by the implementation of optimal locations or spot operations, but that global thinking is instead necessary.

More than ever, the concept of design is vital!

- The design of products so they will be repairable, of course; but also to reflect on the notion of transport with less impact.

- The design of the production process as a whole, taking into account the entire Supply Chain (including suppliers and distribution up to the end user).

- The design of the Supply Chain and its ability to deal with various uncertainties (bad weather, viruses, conflicts, etc.) to ensure continuity of service and / or resilience.

Thinking on circularity cannot be done without the involvement of current and future Supply Chain teams. Flow simulation tools will be at the heart of these approaches for supporting decisions and identifying truly good ideas: those which will have a real impact on the extra-financial balance sheet.

This paradigm shift has already allowed new professions to appear and we are only at the beginning.

And you, as a Supply Chain Manager, do you already have a plan that integrates these 3 design dimensions for a supply chain that performs by being more circular?