In the broad themes of the industry of the future, you have undoubtedly already come across the term “digital twin”.

The main objective of using this technology is to represent the flows (physical / information / financial) of an organization in order to project itself into different versions of reality and to help in decision-making.

What are the advantages of a digital twin?

Using this digital double, you can test a large number of ideas, as well as modifications to them, by using a scripting logic called “What-if?” for simulating the results of future scenarios.

In fact, when this twin is available, you can afford to test any and all ideas that you and your teams come up with because error is allowed and, above all, it will have no impact on your industrial performance at this stage since it remains merely a virtual scenario.

With this tool you may find that your ideas for change that initially seemed relevant were actually not; or, on the contrary, ideas that you did not believe would bring results ended up being surprisingly good!

At AGILEA, this powerful decision support tool has been in use for more than 10 years. We are also seeing the interest of industrial Supply Chain players increasing year after year, regardless of the size of the company.

How can this trend and the interest in simulation be explained?

Flow simulation (whether discrete event, multi-agent or system dynamics, for example) is not a recent tool. Work on these topics began more than forty years ago [1]!

So why then are these methods so relevant today? The answer lies in the following two key points for its democratization that are now available to all companies:

- Useful data. When you want to create a digital twin as well as the processes associated with your organization, this is a must. Companies, small or large, now have in their information systems the vast majority of the data necessary for carrying out simulation projects.

- Computing power. As mentioned in the introduction, the main advantage of a digital twin is in its ability to test a large number of scenarios (“What-if?” processes). A simulation can now be done quickly (in seconds, minutes or hours), depending on the scope of the study and the level of detail of the model. It is now possible to test ideas almost instantly and to quantify their impacts (in terms of cash, inventory, delivery times, etc.).

What are the potential applications?

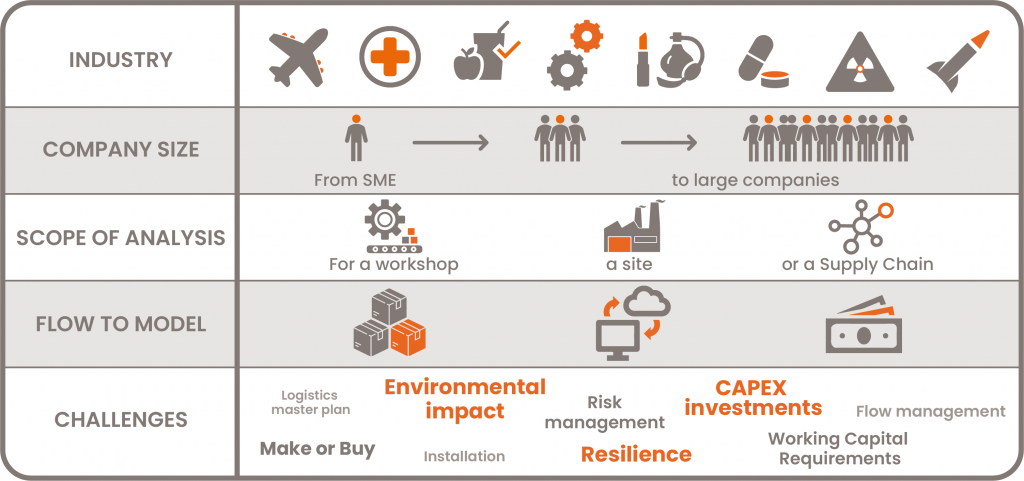

In the table below, we present some fields of application for the numerous simulation projects that have been carried out by AGILEA:

As you can see, the range of possibilities for these methods is immense and suitable for many cases. And this is only becoming reinforced with the growing interest of manufacturers in digitalization, the integration of the concept of resilience or even, for example, the desire to evaluate the organization and sizing of its physical and financial flows over periods of several years. For example, it is a robust decision support tool for the Sales & Operations Planning process.

So why use simulation on your site, on your Supply Chain?

- You have a problem and need to make decisions on a system that at first glance seems overly complex to you.

- You want to quantify improvements, project your indicators “into the best of all possible worlds”, but you know very well that it is the sources of variability (internal or external) and uncertainty that have a major impact your organization.

- You have heard of this “digital twin” concept, but you just cannot see concretely how a project of this type could help your organization.

If at least one of these categories applies to you, it might be beneficial to take a few minutes to look into it and discuss the topic with us.

Don’t hesitate to get in touch with us to find out more about about digital twins!

[1] : “Fishman, G. S. (1978). Principles of discrete event simulation.”